15OCT 2013

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

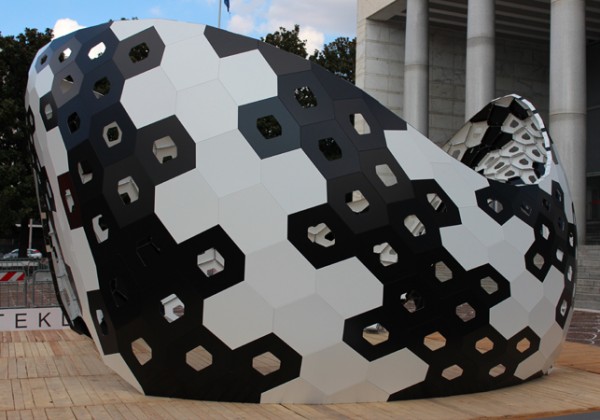

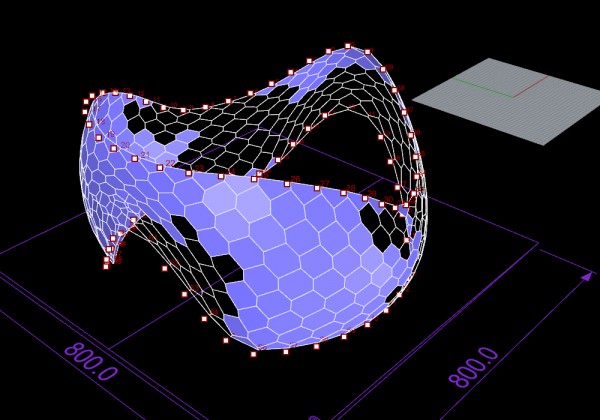

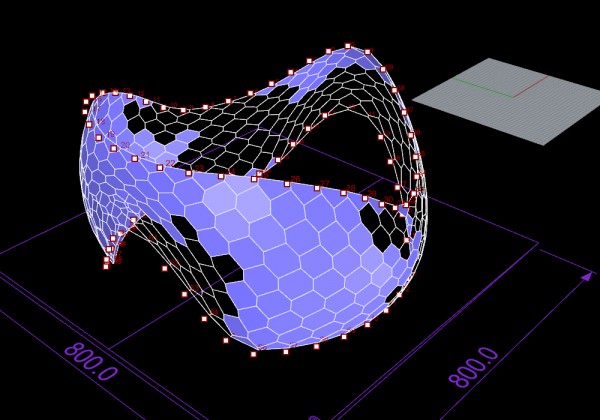

The structure forms a ring with an elliptical base of diameters of 6.37 x 6.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

The structure forms a ring with an elliptical base of diameters of 6.37 x 6.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla66 meters and a maximum height of 3.51 meters.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla66 meters and a maximum height of 3.51 meters.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla It has two axial openings of the maximum height of 2.22 meters.Just the need to achieve the two openings, identifying a crossing axis of the structure, has traced the process for the modeling of the ring.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla It has two axial openings of the maximum height of 2.22 meters.Just the need to achieve the two openings, identifying a crossing axis of the structure, has traced the process for the modeling of the ring.

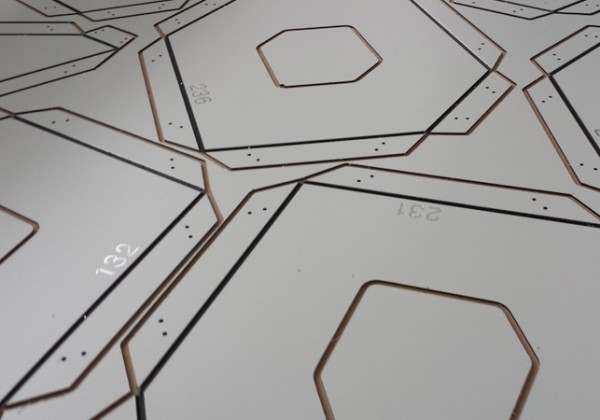

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + TeklaIn parallel, for each project hypothesis has occurred the possibility of its discretization in hexagons, and their subsequent planarization.

Thanks to the use of Kangaroo, the plug-in Grasshopper realized by Daniel Piker, were septate the constraint for the calculation of the planarization of all the elements, and then the final shape.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + TeklaIn parallel, for each project hypothesis has occurred the possibility of its discretization in hexagons, and their subsequent planarization.

Thanks to the use of Kangaroo, the plug-in Grasshopper realized by Daniel Piker, were septate the constraint for the calculation of the planarization of all the elements, and then the final shape.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla These last concerned both the conditions that guaranteed the flatness of the hexagonal elements, both the fixed points from which the structure was not to leave because ensured the offloading to shore of the forces along the openings of the portals, and at the section ring with more weight.In particular of these solutions was verified: the calculation time, the number of pieces, the result in terms of planarization of all the surfaces, their deformation and the approximation of the initial surface. Was noted the deformation and the orientation of the hexagons in relation to the form tested multiple times.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla These last concerned both the conditions that guaranteed the flatness of the hexagonal elements, both the fixed points from which the structure was not to leave because ensured the offloading to shore of the forces along the openings of the portals, and at the section ring with more weight.In particular of these solutions was verified: the calculation time, the number of pieces, the result in terms of planarization of all the surfaces, their deformation and the approximation of the initial surface. Was noted the deformation and the orientation of the hexagons in relation to the form tested multiple times.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla It is then verified the structure subjected to the force of its own weight trying to verify the nature and intensity of the deformation that was suffering. Special thanks at this stage goes to research conducted by Luca Patruno and Domenico Melchionda of the University of Bologna.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla It is then verified the structure subjected to the force of its own weight trying to verify the nature and intensity of the deformation that was suffering. Special thanks at this stage goes to research conducted by Luca Patruno and Domenico Melchionda of the University of Bologna.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

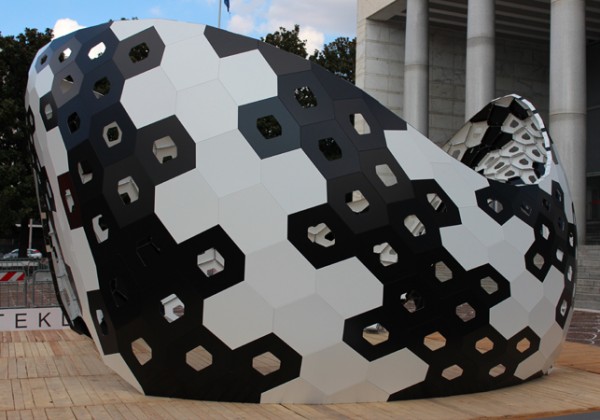

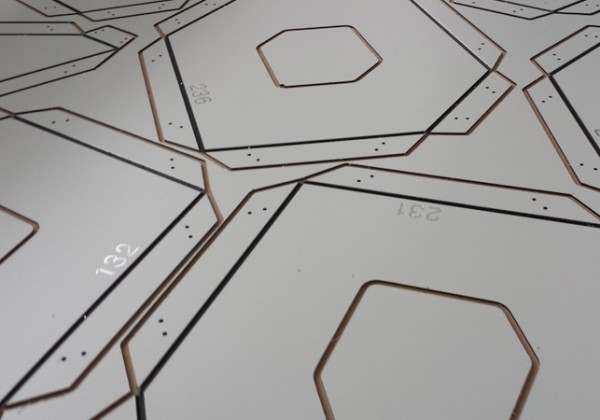

At the same time occurred for each project hypothesis also possible realization in terms of: cutting times, the material used, the assembly system.The pavilion uses about 65 square meters of Etalbond, aluminum sandwich plastic aluminum, which for its flexibility, has allowed us to realize the coupling system of the panels by simply bending the material to the inner side.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

At the same time occurred for each project hypothesis also possible realization in terms of: cutting times, the material used, the assembly system.The pavilion uses about 65 square meters of Etalbond, aluminum sandwich plastic aluminum, which for its flexibility, has allowed us to realize the coupling system of the panels by simply bending the material to the inner side.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla In the design phase has therefore made a finned board that followed the sides of the hexagon. On each of these fins were then made 4 holes for the housing of the nuts and bolts securing the adhesion of the pieces to one another. They were used bolts and nuts type M-8, 5 diameter, length 16, equipped with washers.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla In the design phase has therefore made a finned board that followed the sides of the hexagon. On each of these fins were then made 4 holes for the housing of the nuts and bolts securing the adhesion of the pieces to one another. They were used bolts and nuts type M-8, 5 diameter, length 16, equipped with washers.

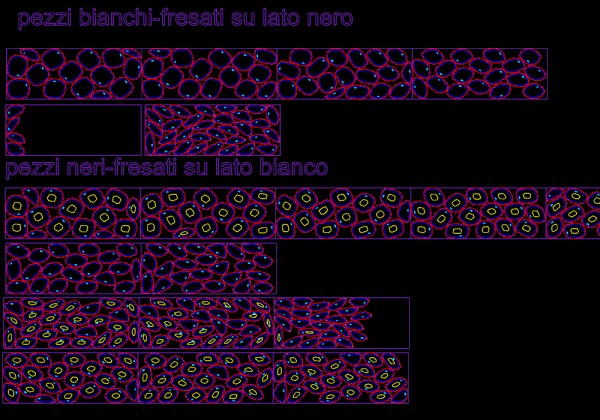

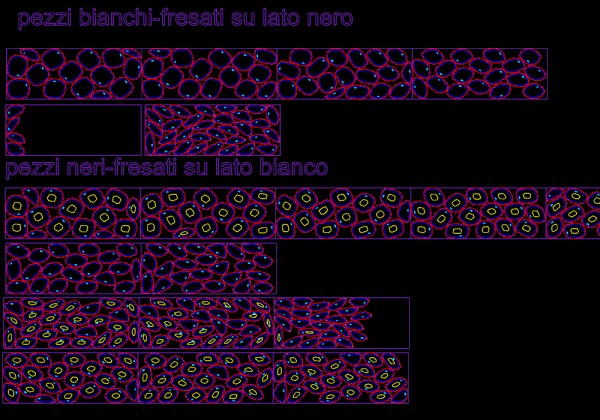

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + TeklaThe final pieces were cut in 24 hours (divided in 3 days, including the handling of the material on the machine) with a cutter 3 axes plan 400cmx150cm, using about 95 square meters of material with a usage rate of 68%Finally it was chosen the pattern of color through the definition in GH ‘pattern seeker‘, generated by Andrea Graziano of Co-de.iT, similar to that already used for the Cocoon I.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + TeklaThe final pieces were cut in 24 hours (divided in 3 days, including the handling of the material on the machine) with a cutter 3 axes plan 400cmx150cm, using about 95 square meters of material with a usage rate of 68%Finally it was chosen the pattern of color through the definition in GH ‘pattern seeker‘, generated by Andrea Graziano of Co-de.iT, similar to that already used for the Cocoon I.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla.

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

Maker Faire Rome: Cocoon Evo Pavillion / Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

Posted in Architecture - Pavilion by * FORMAKERS

Cocoon EVO Pavillion is the installation presented at the Maker Faire Rome from Mediterranean FabLab + Co-de-iT + PicernoCerasoLab realized thanks to the machines and the professionalism of Tekla‘s team.The pavilion, designed as an entry point to the fair, is the evolution of a previous work made of corrugated cardboard, the result of a workshop organized by the Medaarch. © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla © Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

© Mediterranean FabLab + Co-de-iT + PicernoCerasoLab + Tekla

Comments

No comments

Sign in »